MARKETING ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MARKETING ENGINEERS

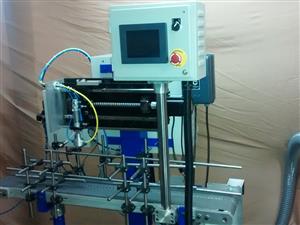

Ultrasonic Plasting Welding

Ultrasonic horns are designed with an FEA (Finite Element Analysis) simulation program that allows our engineers to observe the vibratory action of the horn prior to fabrication. Segmented and adjustable fixtures are built to ensure a secure fit with the molded plastic parts. Contoured fixtures and tools for irregularly shaped parts. Ultrasonic horns are inspected for even amplitude. For added strength and durability, carbide facing or chrome plating is applied. Peripheral devices to clamp, hold and align opposing parts are also available.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.